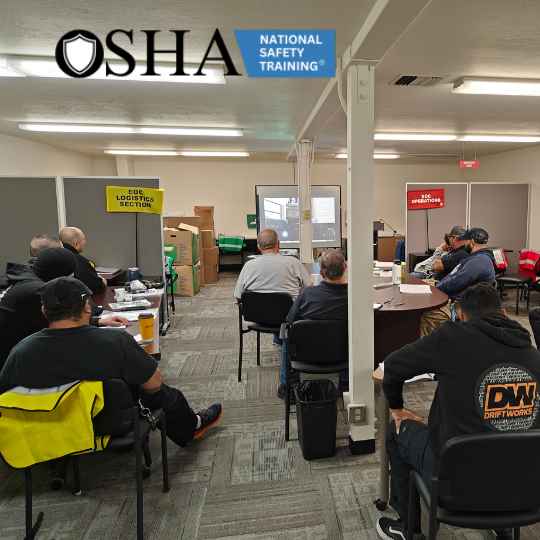

On Site Forklift Safety Training and Certification

Get a Quote/Schedule for Onsite Training

Best Priced & Value Guranteed!

The Value of 3rd Party On Site Forklift Safety Training:

MEWP

Forklift Types or Classes

- Class 1 – Electric Forklift

- Class 2 – Electric Narrow Aisle Trucks

- Class 3 – Motor Pallet Jacks

- Class 4 – Combustion Engine Forklifts (Cushion Tire)

- Class 5 – Rough Terrain Forklifts (Pneumatic Tires)

- Class 6 – Electric and Combustion Tractors

- Class 7 – Rough Terrain Forklifts

One Day Onsite Forklift Training Agenda

Duration: Between 4-6 hours depending on type of training.

Session 1: Introduction to Forklifts and Safety

Participants are introduced to the fundamental concepts of forklifts and safety. The session commences with a warm welcome and introductions to foster a positive learning environment. An overview of the training program is provided, outlining the key topics and objectives to be covered throughout the training. Emphasis is placed on the benefits of onsite forklift training, highlighting its role in enhancing workplace safety and preventing accidents. Participants are made aware of the critical role they play in improving safety standards and are encouraged to actively engage in the training to promote a culture of safety within their workplace. This session sets the stage for a focused and safety-conscious learning experience.

Session 2: Types of Forklifts and Components

Participants delve into an exploration of various forklift types and their specific applications. They gain an understanding of the seven main types of forklifts, such as counterbalance, reach trucks, and pallet jacks, along with their distinct uses in different industrial settings. Additionally, this session includes a thorough examination of forklift components and controls, ensuring that participants become familiar with the machinery’s intricacies. Special emphasis is placed on the safe and effective use of these controls, reinforcing best practices to maximize operational efficiency while prioritizing safety. Ultimately, this session equips participants with valuable knowledge to select the right forklift for specific tasks and operate it competently, promoting a safer and more productive workplace environment.

Session 3: Pre-Operational Checks and Forklift Stability

Participants learn about the vital importance of pre-operational checks and forklift stability. Pre-operational checks are essential to ensure the forklift’s safety and functionality, minimizing the risk of accidents and costly maintenance. During these checks, operators inspect various components, including tires, fluid levels, forks, controls, lights, and brakes, looking for signs of damage or malfunction. In the context of forklift safety, tag out parameters involve using tags to mark a forklift as “out of service” if it has serious issues, specifying the reason for tagging out, and prohibiting its operation until repairs are completed by authorized personnel. This session emphasizes the significance of proactive safety measures and compliance with regulatory requirements to maintain a safe and efficient forklift operation environment.

Session 4: Operating a Forklift

Participants engage in practical, hands-on experience with forklift operation within a controlled environment. This immersive segment of the training focuses on building the skills necessary to operate a forklift safely and effectively. Participants learn the art of maneuvering, emphasizing the importance of precise steering and driving techniques to navigate confined spaces and challenging terrains with confidence. Additionally, basic load handling skills are honed, covering essential tasks such as picking up, placing, and stacking loads. This session equips participants with the practical know-how required to operate a forklift proficiently, laying the foundation for safe and efficient forklift operations in real-world workplace scenarios.

Session 5: Hazard Awareness and Evaluation

Participants delve into the critical aspects of hazard awareness and evaluation. The session begins with an emphasis on identifying potential workplace hazards, instilling in participants a heightened sense of awareness regarding their surroundings. Strategies for avoiding common forklift accidents are discussed in detail, providing valuable insights into accident prevention and risk mitigation.

The session also includes a practical evaluation component, where participants have the opportunity to apply their forklift operation skills in a real-world context. This evaluation serves as a crucial assessment of their ability to operate a forklift safely and efficiently. By analyzing their performance in practical scenarios, participants gain a deeper understanding of their strengths and areas for improvement, ultimately contributing to a safer and more proficient forklift operation in their workplace.

Session 6: Certification and Course Conclusion

Successful participants receive well-deserved certificates acknowledging their achievement and competence in forklift operation and safety.

The session also includes a comprehensive review of key takeaways and safety reminders from the training program. This recap reinforces the crucial knowledge and skills gained throughout the training, ensuring that participants leave with a solid understanding of forklift safety and operation.

Furthermore, a Q&A and feedback session is conducted, providing an opportunity for participants to seek clarification on any remaining doubts and share their insights and experiences. This interactive segment encourages open communication and the exchange of valuable feedback, facilitating continuous improvement in both forklift operations and future training programs. Ultimately, Session 6 serves as a fitting conclusion to the training, empowering participants with the tools and confidence to contribute to a safer and more proficient forklift operation within their workplace.

Locations

California:

Los Angeles, CA: Forklift Certification Training in Los Angeles

San Francisco, CA: Forklift Certification Classes in San Francisco

San Diego, CA: Get Certified for Forklifts in San Diego

Sacramento, CA: Forklift Certification near Sacramento, CA

Fresno, California: Forklift Training and Certification in Fresno

Long Beach, CA: Forklift Training and Certification in Long Beach

Palmdale, CA: Forklift Training and Certification in Palmdale

Irvine, CA: Forklift Training and Certification in Irvine

Arizona:

Phoenix, Arizona: Forklift Certification Courses in Phoenix

Tucson, Arizona: Forklift Operator Training in Tucson

Mesa, Arizona: Mesa’s Forklift Certification Classes

Nevada:

Las Vegas, Nevada: Las Vegas Forklift Certification Classes

Henderson, Nevada: Forklift Training in Henderson, NV

Reno, Nevada: Reno’s Forklift Certification Providers

Oregon:

Portland, Oregon: Forklift Certification in Portland, OR

Eugene, Oregon: Eugene Forklift Training and Certification

Salem, Oregon: Salem’s Forklift Certification Schools

Utah:

Salt Lake City, Utah: Forklift Certification in Salt Lake City

West Valley City, Utah: West Valley City Forklift Training

Provo, Utah: Forklift Certification Classes in Provo

Washington:

Seattle, Washington: Forklift Certification in Seattle

Spokane, Washington: Spokane Forklift Training and Certification

Tacoma, Washington: Tacoma Forklift Certification Classes

Colorado:

Denver, Colorado: Forklift Certification Classes in Denver

Colorado Springs, Colorado: Forklift Certification in Colorado Springs

Fort Collins, Colorado: Forklift Certification in Fort Collins

Texas:

Houston, Texas: Forklift Certification in Houston

San Antonio, Texas: San Antonio Forklift Training and Certification

Dallas, Texas: Dallas Forklift Certification Classes

Austin, Texas: Austin’s Forklift Certification

Florida:

Miami, Florida: Forklift Certification in Miami

Orlando, Florida: Orlando Forklift Training and Certification

Tampa, Florida: Forklift Certification Classes in Tampa

Forklift Certification:

In the dynamic world of logistics and material handling, forklift certification stands as a crucial milestone for professionals aiming to excel in safety and efficiency. This comprehensive guide delves into the essentials of forklift certification, outlining the process, benefits, and key considerations to ensure you are fully equipped to navigate this vital aspect of your career. Whether you’re a novice operator or a seasoned veteran, understanding the nuances of forklift certification is paramount in maintaining a safe and productive workplace.

The Importance of Forklift Certification:

Forklift certification is not just a regulatory requirement; it’s a fundamental aspect of workplace safety. According to OSHA, improper forklift operations cause about 100 fatal accidents annually. Certification ensures operators are equipped with the necessary skills and knowledge to handle forklifts safely, reducing the risk of accidents and injuries. It’s also a legal necessity. OSHA mandates that all forklift operators must be properly trained and certified to handle these vehicles.

How to Get Forklift Certified:

The path to becoming a certified forklift operator involves several key steps. Firstly, one must undergo a training program that covers both practical skills and theoretical knowledge. This training typically includes understanding the different types of forklifts, learning about safety protocols, and mastering operational techniques. After completing the training, candidates must pass an evaluation at the workplace on the machine they will operate, which often includes a written test and a practical skills assessment.

Understanding the Forklift License:

A forklift license is often used interchangeably with forklift certification, but it’s important to understand the nuances. While certification focuses on training and skill assessment, a forklift license is a formal document that proves an operator has undergone the necessary training and evaluation to operate a forklift safely. This license is typically issued by the training provider upon successful completion of the certification process.

Importance of a Forklift License in the Workplace:

Holding a valid forklift license is a requirement for operating forklifts in most workplaces. It serves as proof that the operator has received the necessary training and is aware of the safety protocols. Employers are responsible for ensuring that all forklift operators on their premises are licensed, as part of compliance with workplace safety regulations.

OSHA Forklift Certification:

Selecting the right training program is crucial. Prospective trainees should look for programs that are OSHA-compliant and offer a comprehensive curriculum. It’s also important to consider the mode of training – whether it’s in-person or online. Each has its benefits; in-person training offers hands-on experience, while online programs provide flexibility.

Benefits of Being a Certified Forklift Operator:

It’s a Federal Law, Operators must be certified before they operate any type of forklift. Certification opens up numerous opportunities. Certified operators are often preferred by employers, leading to better job prospects and potentially higher wages. Moreover, being certified underscores a commitment to safety, which is highly valued in industrial settings.

How long does a forklift certification last:

Forklift certification is not a one-time event. OSHA requires operators to renew their certification every three years. This recertification process ensures that operators stay up-to-date with the latest safety protocols and operational techniques.

Common Challenges and Solutions in Forklift Training:

One common challenge faced by many is balancing the time commitment required for training with their current job responsibilities. Online training programs can be a solution here, offering the flexibility to learn at one’s own pace. Another challenge is the anxiety associated with the practical evaluation. Here, hands-on practice and familiarization with the equipment can be immensely helpful.

Online Forklift Certification

Online forklift certification typically involves a series of instructional modules that cover all the theoretical aspects of forklift operation, including safety guidelines, operational procedures, and OSHA regulations. These modules can often be accessed at any time, allowing learners to progress at their own pace. Upon completing the online coursework, candidates usually need to pass an assessment to demonstrate their understanding of the material.

Practical Training and Evaluation:

While online programs efficiently cover the theoretical aspects of forklift operation, practical skills are just as crucial. Therefore, many online certification programs recommend or require candidates to complete a hands-on training session under the supervision of a qualified supervisor. This training can sometimes be arranged through candidate’s workplace.

Benefits of Online Certification:

One of the main advantages of online forklift certification is its accessibility. It allows individuals to start or continue their forklift training without the need to travel or adhere to a fixed class schedule. Additionally, online programs can be more cost-effective than traditional in-person training. They also enable learners to revisit the material as often as needed, which can enhance understanding and retention.

Clarifying the Term: Is It “Fork Lift” or “Forklift”?

In the realm of material handling and logistics, terminology is key, and one common point of confusion is whether the correct term is “fork lift” or “forklift.” The correct and widely accepted term in the industry is “forklift,” written as one word. This distinction is important not only for professional communication but also for clarity in training, certification, and safety guidelines. The term “forklift” encompasses a range of powered industrial trucks used for lifting and moving materials over short distances. While “fork lift” might occasionally be seen in informal use, it’s essential for professionals in the field to use the standardized term “forklift” to ensure consistency and accuracy in all aspects of their work, from official documentation to daily operations.

Exploring the 7 Classes of Forklifts and Their Specific Uses

The world of forklifts is diverse, with different types designed for various applications. Understanding the seven classes of forklifts is crucial for selecting the right equipment for specific tasks. Each class caters to different working environments and load-handling requirements.

Class 1: Electric Motor Rider Trucks

These forklifts are powered by electric batteries and are commonly used indoors, especially in warehouses. They are known for their quiet operation and absence of emissions. Class 1 forklifts are ideal for loading and unloading pallets, transporting goods, and general warehouse stacking.

Class 2: Electric Motor Narrow Aisle Trucks

Designed for tight spaces and narrow aisles in warehouses, these electric-powered forklifts are perfect for places where space is at a premium. They include reach trucks and side loaders, commonly used in stacking pallets and reaching high shelves without needing much maneuvering space.

Class 3: Electric Motor Hand Trucks or Hand/Rider Trucks

These are hand-operated electric forklifts, where the operator is either walking behind the vehicle or riding on a small platform. They are used for low-level picking and short-distance transportation of goods, ideal for loading docks, and smaller warehouses.

Class 4: Internal Combustion Engine Trucks (Solid/Cushion Tires)

Equipped with solid tires and an internal combustion engine, these forklifts are used primarily indoors on smooth surfaces. They are suitable for moving pallets and handling a variety of materials within a warehouse or distribution center.

Class 5: Internal Combustion Engine Trucks (Pneumatic Tires)

These forklifts have pneumatic tires and are powered by internal combustion engines. They are versatile and can be used both indoors and outdoors. Class 5 forklifts are commonly found in lumber yards, construction sites, and other outdoor applications due to their ability to navigate rough terrain.

Class 6: Electric and Internal Combustion Engine Tractors

This class includes both battery-powered and internal combustion engine tractors. They are versatile and used for towing rather than lifting, ideal for hauling loads over long distances within industrial complexes or airports.

Class 7: Rough Terrain Forklift Trucks

Specifically designed for outdoor construction sites and rugged environments, these forklifts have large, aggressive tread tires. They are commonly used in lumber yards, construction sites, and other outdoor applications where uneven and rough surfaces are prevalent.

Each class of forklift has its unique strengths and is designed to meet specific needs in material handling. Understanding these classes helps businesses choose the right forklift for their specific operational requirements, ensuring efficiency, safety, and productivity in their material handling tasks.

Power Industrial Truck (PIT) AKA Forklift

In the industrial and logistics sectors, Power Industrial Trucks (PITs) are indispensable tools that play a crucial role in the movement and handling of materials. These vehicles, encompassing a wide range of machinery, are designed to lift, carry, stack, or tier materials. This article aims to shed light on what PITs are, their various types, applications, and the importance of safety and training in their operation.

Defining Power Industrial Trucks:

A Power Industrial Truck is a motorized device used to transport, lift, or pull materials over short distances. Unlike heavy equipment used for earth moving, PITs are primarily used in warehouses, factories, and distribution centers. They are categorized under the umbrella of material handling equipment and are essential in managing the supply chain and logistics operations.

Types of Power Industrial Trucks:

PITs come in various forms, each designed for specific tasks and environments:

Forklifts: The most recognized type of PIT, used for lifting and moving loads on pallets.

Pallet Jacks: Smaller than forklifts, these are used for moving pallets within a warehouse.

Order Pickers: Used in warehouses to pick and deliver materials from storage.

Stackers: Designed to stack pallets at various heights.

Tow Tractors: Used for towing loads rather than lifting them.

Reach Trucks: Ideal for reaching high shelves in narrow warehouse aisles.